The ease of maintenance and serviceability of a Metal Sheet Laser Cutting Machine can have a significant impact on downtime in several ways:

- Reduced Maintenance Time: If a laser cutting machine is designed for easy maintenance, tasks such as cleaning, lubrication, and component replacement can be performed quickly and efficiently. This reduces the time required for routine maintenance, minimizing downtime associated with scheduled service intervals.

- Quick Access to Components: A laser cutting machine with a design that allows easy access to critical components such as the laser source, optics, cutting head, and motion system facilitates faster troubleshooting and repair. Maintenance personnel can swiftly identify and address issues, minimizing the duration of unplanned downtime.

- User-Friendly Interface: Intuitive control interfaces and diagnostic tools simplify troubleshooting procedures and enable operators to identify and resolve issues without extensive training or technical expertise. This streamlined approach to maintenance reduces the time needed to diagnose and rectify problems, minimizing production interruptions.

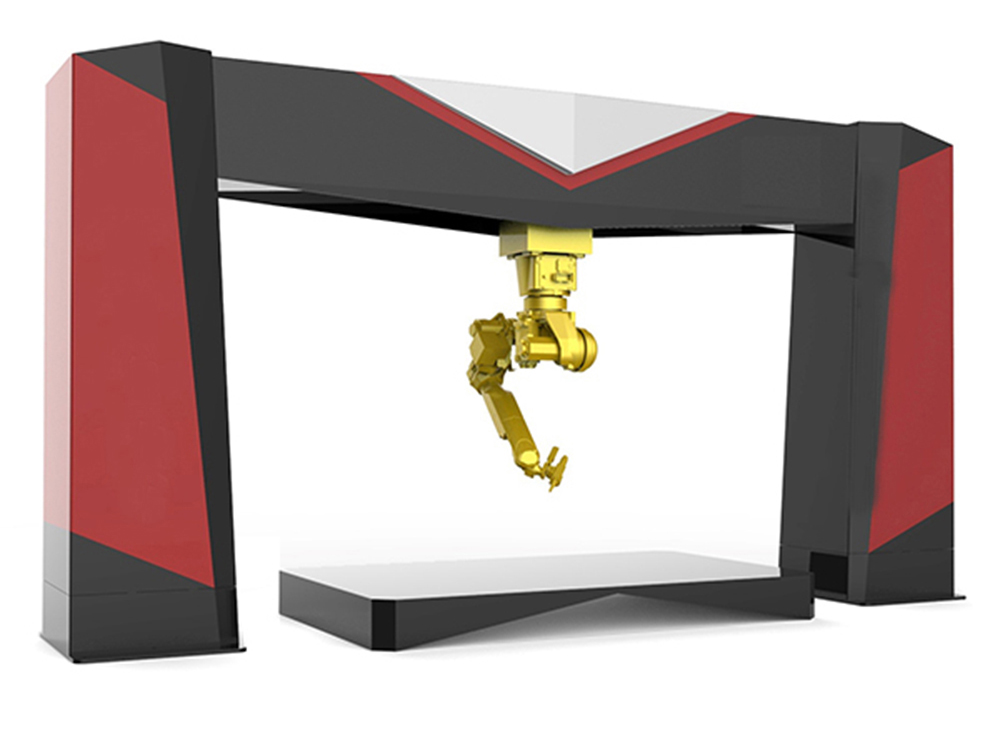

- Modular Design: A Metal Sheet Laser Cutting Machine with a modular design allows for the easy replacement of individual components or subsystems. This modular approach enables maintenance personnel to quickly swap out faulty parts, reducing the time required for repairs and minimizing downtime.

- Remote Monitoring and Support: Advanced laser cutting machines may feature remote monitoring capabilities that allow service technicians to remotely diagnose issues and provide guidance to onsite personnel. Remote support can expedite troubleshooting and repair processes, China Metal Sheet Laser Cutting Machine factory minimizing downtime by reducing the need for onsite visits from service technicians.

- Predictive Maintenance Features: Some laser cutting machines incorporate predictive maintenance features that monitor equipment condition and performance in real-time. By detecting potential issues before they lead to machine failure, predictive maintenance helps prevent unplanned downtime and allows maintenance to be scheduled proactively during planned maintenance windows.

- Comprehensive Training and Documentation: Laser cutting machine manufacturers may provide comprehensive training programs and documentation to equip operators and maintenance personnel with the knowledge and skills required to perform maintenance tasks effectively. Well-trained personnel can address maintenance issues promptly, reducing the duration of downtime caused by equipment malfunctions.

- Spare Parts Availability: Availability of spare parts is crucial for minimizing downtime during repairs. Manufacturers that maintain adequate spare parts inventory and offer expedited shipping options can ensure that replacement parts are readily accessible when needed, minimizing the time required to get the machine back up and running.

Overall, the ease of maintenance and serviceability of a Metal Sheet Laser Cutting Machine directly impacts downtime by enabling quick and efficient maintenance procedures, reducing the time required for troubleshooting and repair, and facilitating proactive maintenance practices that prevent unplanned interruptions to production.