Globe valves and gate valves are two common types of valves used in various industries, including chemical, petrochemical, and oil refineries. While both types of valves serve similar purposes, there are some key differences between them. In this article, we will explore the main differences between globe valves and gate valves, including their design, operating principles, and applications.

Design and Operating Principles

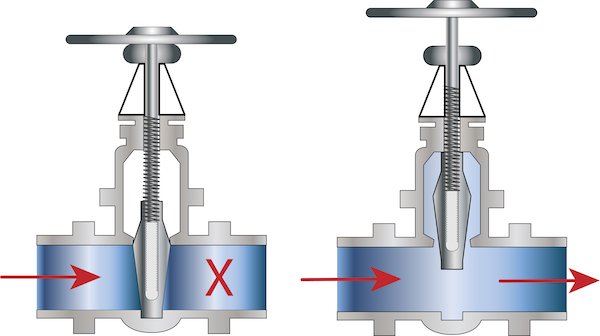

Globe valves and gate valves differ in their design and operating principles. Globe valves are typically cylindrical and have a globe-shaped valve seat that moves up and down within the valve body. The valve seat is connected to a stem that rotates to open and close the valve. On the other hand, gate valves have a rectangular or square valve body with a gate-shaped valve seat that opens and closes horizontally. The valve seat is connected to a stem that rotates to open and close the valve.

One of the main differences between globe valves and gate valves is their operating principle. Globe valves are operated by a lever or handle that rotates the valve stem, while gate valves are operated by a handle or lever that moves the valve seat up and down. Additionally, globe valves are typically more compact and lightweight than gate valves, making them ideal for use in smaller applications.

Applications

Globe valves and gate valves are used in a wide range of industries, including chemical, petrochemical, and oil refineries. They are commonly used in pipelines, tanks, and vessels to regulate the flow of fluids and gases. Globe valves are often used in applications where a simple, compact valve is required, such as in small pumps or compressors. Gate valves, on the other hand, are often used in applications where a more robust valve is required, such as in large pipelines or tanks.

Conclusion

In conclusion, globe valves and gate valves are two common types of valves used in various industries. While both types of valves serve similar purposes, there are some key differences between them, including their design, operating principles, and applications. Understanding the differences between these two types of valves is essential for selecting the appropriate valve for a particular application. By considering factors such as compactness, robustness, and operating simplicity, engineers and technicians can choose the best valve for their specific needs.